Basket Mill Manufacturers

Basket Mill Manufacturers in India

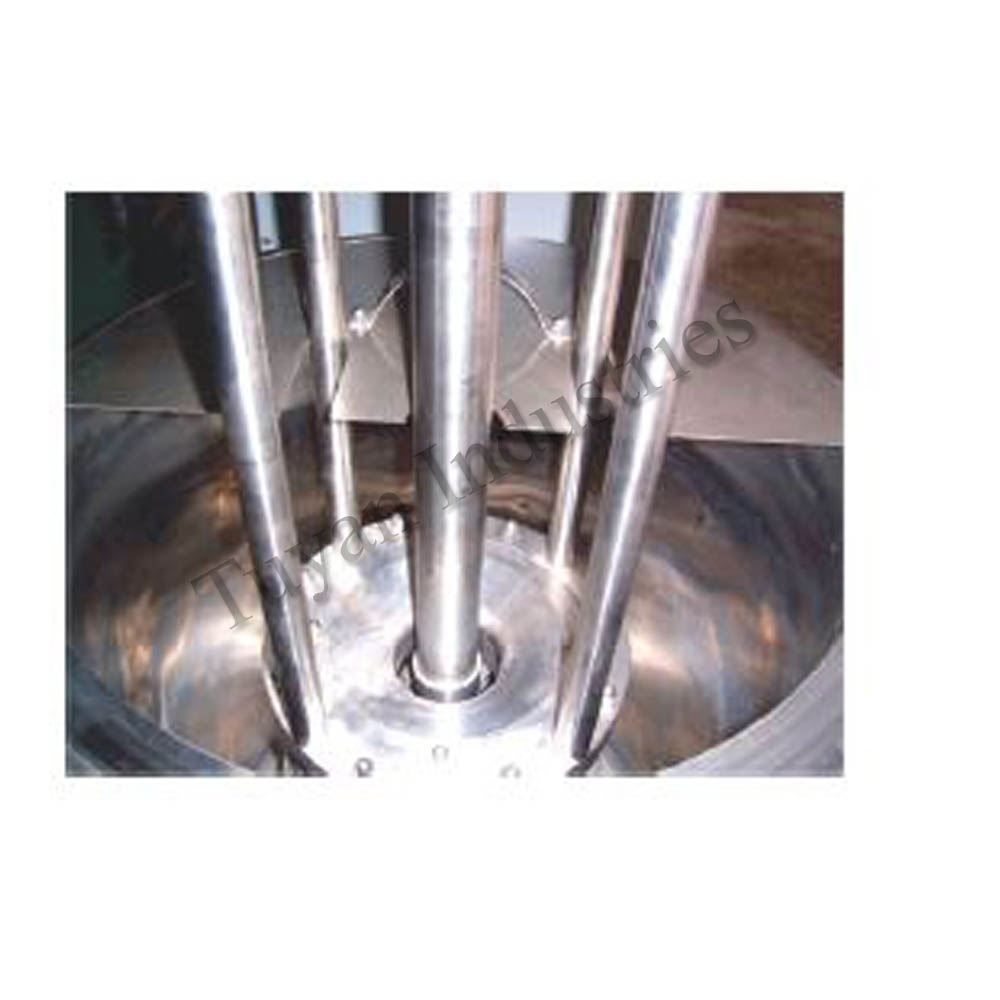

Tuyan Industries is a well-known & recognized industry is leading the Basket Mill Manufacturers in India. We have a team of experts engineers who has able to manufacturers the top-notch quality Basket Mills as per customers requirements. The basket mill machine is a wet grinding machine that is suitable for middle and viscosity fluids & batch type production equipment. When the irregular collision between the grinding beads and particle in the all-direction the size of the materials becomes smaller when powerful energy generates.

Basket mill is suitable for coatings, inks, pigments, colourants, pesticides, cosmetics and other applications with high requirements of fineness.

The basket mill is developed for additional production processing by integration and milling which make two processes into one and help to increase the production and productivity significantly.

It can complete dispersing, premixing, dispersion and shearing and milling at the same time through one machine and one container, which improves efficiency greatly and help to reduce the waste materials.

The basket mill is more convenient to use and clean and suitable for grinding more varieties of materials compared to other grinding mills machine.

Tuyan Industries, Basket Mill Manufacturers in India has years of experience and expertise in manufacturing the high-efficiency and high-performance basket mills.

How Does Basket Mill Work?

Basket mills have been employed very successfully in the process of batch grinding of paints and for pigment dispersion. Basket mills are designed for a combined process of material premixing, blending, dispersion, and grinding in a single operation. The batch dispersal system has been redefined in this basket mill. This system provides a high degree of dispersion that can be many times more efficient than traditional media milling system. The quality and performance of Basket Mills manufactured by the Tuyan Industries have earned immense acclaim in many industries in India market. The basket mill consists of a milling basket or a grinding chamber which is immersed in a raw material process tank. The grinding chamber grinds the raw material. Initially, the integrated impeller or blade begins to disperse and pumps the raw material into the media containing the grinding chamber. The combined effect of rigid milling discs and properly chosen grinding beads suggests high shearing and attachment forces resulting in finer grinding and dispersion. The separator at the bottom of the basket prohibits beads from being passed into the raw material in the pot. The milled material is being poured into the vessel through the separator. This process is repeated until the entire mass of the product is properly mixed and dispersed. The basket mills are also known as batch mills and have been around in the milling industry for decades and are still in high demands because of the benefits that this one single machine has to endeavour the wet grinding industry. The basket mill is an exceptionally versatile dispersion system that can be applied to a wide range of processing industries. The ring mill is specifically engineered to allow complete mixing and dispersion in a single tank, providing the highest level of efficiency and reliability. From dry pigments, all can be completed to disperse without changes to the tank or blade, without time-consuming clean-ups and operator interaction. The simplicity of Tuyan Industries produced basket mill machines that allow up to 99.99% for higher material yields from batch to batch. This includes less cleaning and reduction of waste solvents. The process of premixing, dispersion, compounding, and dilution is completed in a single unit requiring less space, less time, and less energy to achieve larger results. No siphons, funnels, valves, spare holders and beyond. Simple cleaning and minimal misfortune when changing items. Contradictory to other granular gear, it is progressively useful for spotting and proper over-classification of materials. Basket Mill Manufacturers in India is offering basket mill machine within reasonable rates. They also require minimal maintenance. The simplicity of Tuyan Industries manufactured Basket Mill system allows for very high material yields from batch to batch, as high as 99.99%. This means less clean-up and a reduction in waste solvents. Premixing, dispersion, compounding and dilution are all accomplished in a single unit that requires less space, less time and less energy to achieve bigger results. No siphons, funnelling, valves, extra holders and so forth are required. Simple cleaning and least item misfortune when changing the item. Contrasted with other granulating gear, it is progressively helpful to spotless and reasonable for pounding more assortments of materials. Basket Mill Manufacturers in India is offering Basket Mill machine within the reasonable rates. These also require the least maintenance.

Advantages:

Dispersing with milling as one procedure

No pumps, piping, valves, additional containers etc. required.

Promoting the circulation of material effectively

No dead zone due to effective mill base circulation

Avoiding the blind angle while the material is cycled

It is more convenient to disassemble, maintain, and overhaul the design of blocking parts, much less a professional maintainer is required

Fastest grinding

Easy Temp Control

No need grinding media separation

Easy washing

Easy Cooling System With Two Way Cooling System

Easy Dust Control

Easy Tank Holding

Particularly high throughput rate

The specially manufactured construction of baskets and rotors ensure non-metal contamination for the material.

Features:

Suitable for Small industrial batch manufacturing

Stable and convenient hydraulic lift is adopted with solid and

durable structure

Combining dispersing with milling in one procedure: dispersion

and superfine milling to be done within one time

High performance, economic, easy to clean

Inverter available for speed variation

Explosion proof options

Customized design to meet customers' requirements

Belt , manual and Tank clamps for choices